Industrial Air Washers

Are you looking for an industrial air washer that can improve the air quality in your factory? Air washers are an effective solution for improving air quality in factories. Many companies are looking for an air washer that can improve the air quality in their factories.

We have a wide selection of air washers that can suit your needs. Choose from a variety of brands and models to find the perfect air washer for your industry.

What is Industrial Air Washers?

Natural air cooling is the most effective and economic way to way to provide cooling in manufacturing halls, production shop floors, warehouses, packaging, assembly area, electrical room, etc. Air washers work on the concept of evaporation and are thus sometimes called Evaporative Air Cooling Machine.

When it comes to industrial air washers, many companies are looking for an effective solution that can improve the air quality in their factories. The traditional air conditioning systems are often not enough to provide the necessary level of air quality for industrial facilities. That’s where industrial air washers come in. These systems can effectively clean the air and provide a comfortable and healthy working environment for employees.

How Do Industrial Air Washers Work?

It works on the principle of cooling outside air by passing it over water-saturated pads, causing the water to evaporate into it resulting in a lowering of the temperature of the air. Cooled air from these air washers can be fed directly into the cooling space by means of a duct.

These ducts can be made of GI, AI, or SS depending on the type of application. These ducts can be rectangular, square, circular, or oval as per the space available and as per appication requirement.

Benefits of Industrial Air Wahers:

- Improved air quality: Air washers remove contaminants, such as dust, dirt, and pollutants, from the air, resulting in cleaner and healthier air for employees to breathe.

- Increased productivity: Improved air quality leads to a healthier work environment, which can boost employee productivity and reduce sick days.

- Energy efficiency: Air washers use water to clean the air, which can be more energy-efficient than traditional air filtration systems.

- Cost savings: Industrial air washers can help reduce HVAC maintenance costs by removing contaminants from the air, which can reduce wear and tear on equipment.

- Reduced environmental impact: Air washers can help reduce the environmental impact of industrial processes by removing pollutants from the air before they are released into the atmosphere.

Industrial Air Washer Unit is a very energy-efficient means of cooling. These washers have long working life and are available in modular designs.

Synergy Industrial Air Washers are available in the range of 3000 CFM to 80,000 CFM and are manufactured using excellent quality raw materials and the latest technology by our skilled professionals.

In order to ensure quality, air washers are stringently tested on various parameters by our experts. These products are widely acclaimed among clients for their long functional life, corrosion resistance, and low maintenance cost.

Why Choose Synergy Industrial Air Washers

Synergy Industrial Air Washers offer a reliable, efficient, and customizable solution for improving air quality in industrial settings, backed by expert support and service.

- High-quality design and construction

- Efficient air purification

- Energy efficiency

- Customizable options

- Expert support and service

Call For a Quote:

(+91) 9899-461-273

F.A.Q.

Think about Air cooler for cooling yourQ factory or workspace?

Coolers are Natural Humidifiers that work well in extreme heat conditions. The Evaporative cooling effect rises with a rise in temperature without a rise in power consumption.

Think about Air cooler over Air Conditioners ?

For eg., Air coolers are simpler devices compared to ACs. Coolers have comparable demonstrable less cost of maintenance and operations.

Think Capex, Opex while considering plant cooling requirements?

Coolers are CAPEX, and OPEX friendly. The cost of equipment alone can be as low as 14.2% and operation cost as low as 4% when compared with ACs for a fixed floor size.

Think about temperature control while thinking Air Coolers ?

Yes, today it’s possible to have single-phase variable cooling control in air coolers like ours.

Think about Humidity and its effect on coolers ?

Coolers work best in more heat environments and operate effectively even at temperatures above 45 degrees and relative humidity of 77% max.

Think about air coolers for channelized air conditioning ?

Ductable coolers can be put to greater use for focused cooling requirements through “Effective” ducting.

Not think about a healthier choice?

Coolers are pro-natural, they abdicate the ill effects of dehydration which can otherwise cause workplace health disorders.

Contact Us

376, IMT Sector-68, Faridabad, Haryana - 121004

(+91) 98994-61273, (+91) 97111-59834

sales@synergycooler.in

Our Prodcut Range

Jumbo Air Cooler

PP Duct Air Coolers

Portable Air Coolers

Commercial Air Coolers

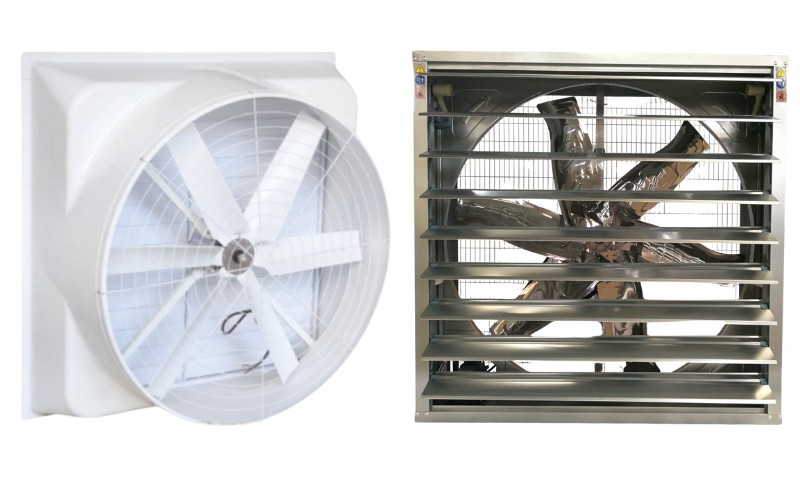

Industrial Exhaust Fans

Metal Standing Fans

SS Body Air Coolers

Industrial Air Washers